Oil

filtration with Magnetic Filter Rod

is necessary for industrial and automotive machinery to function properly, be

dependable, and last for a long time. Disposable filters, cleanable filters,

strainers, and centrifugal separators are just a few of the many options

available to lubrication professionals for filtering and controlling

contamination. The importance of lubricant cleanliness cannot be overstated.

This

article looks at the many ways magnetic filters and separators are used in the

lubrication industry today and explain how particles are separated.

Additionally, a brief introduction to commercial filtration products is

provided.

The

magnet has been crucial in the process of separating ferrous solids from fluid

streams since its inception in the iron ore beneficiation industry. Magnetic

separation and filtration technology has found a useful application even in the

management of contamination from hydraulic fluids and lubricants used in

service.

There

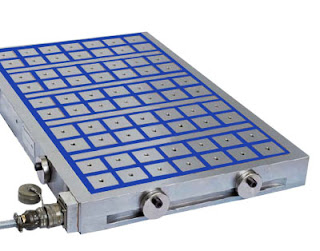

are currently a number of conventional and innovative products on the market

that make use of magnets in a variety of geometries and configurations.

The

function of magnetic filters Auto mechanics, equipment operators, maintenance

technicians, and reliability engineers are aware of the significance of clean

oil for machine reliability. Tribologists and analysts of used oil are also

aware that ferromagnetic (iron or steel) particles can make up as much as 90%

of the oil in some machines.

Iron

or steel metallurgy is typically present on one or both lubricated sliding or

rolling surfaces. These remember frictional surfaces for outfitting,

rolling-component orientation, cylinder/chambers, and so on.

The

majority of conventional mechanical filters are disposable and cost per gram of

particles removed, despite the fact that they can remove particles of the same

size range as magnetic filters from Magnet Factory China.

Utilizing

conventional filtration comes with additional drawbacks, including an increase

in energy and power consumption as a result of the flow restriction imposed by

the medium's fine pore size. The restriction increases proportionally as

particles clog pores, increasing the power required to filter the oil.