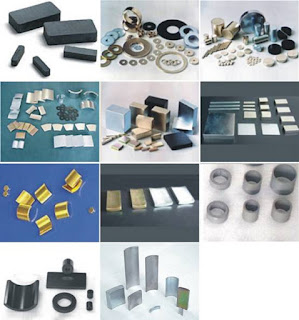

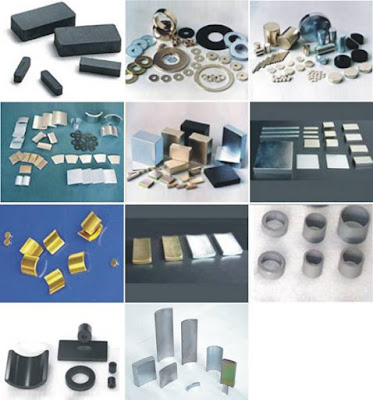

Rare earth or permanent Magnetic Chuck is created from elements within the rare-earth element group of the table of the weather. While once considered rare, these elements are found to be as common as lead or tin. However, their usefulness in permanent didn't become apparent until the rare-earth element was developed within the 1970-1980s.

Neodymium Iron Boron magnets are very similar to samarium cobalt magnets but are often oxidized more easily. Thanks to the very fact that these magnets can easily be corroded, manufacturers often use a surface coating to stop oxidation. they're also high cost magnets but offer a compact design. They are doing not offer the mechanical strength of the opposite three sorts. These magnets offer high energy production and are found in microphones, in-ear headphones, and loudspeakers also as guitar and bass pick-ups. These magnets also are commonly utilized in computer hard drives.

Samarium Cobalt provides better

magnetic strength and temperature resistance than either alnico or ceramic

magnets. Samarium cobalt magnets resist temperatures up to 300 degrees C.

they're somewhat brittle and have a coffee mechanical strength, but are a high

energy product. Search for Samarium Cobalt magnets within the high-end electric

motors used for slot auto racing also as in turbomachinery and traveling-wave

tubes. They’re also effective to be used in cryogenic applications thanks to

their wide temperature stability.

Ceramic/Ferrite magnets are a

composite of iron oxide and barium. While these permanent magnets are low in

cost and have a high force, they're relatively low in energy and in mechanical

strength. Ferrite is an iron-containing material and was used for hundreds of

years before the invention of the properties of the rare-earth element.

Ceramic/Ferrite remains the foremost widely used magnets on the market and is

found in electronic inducers, transformers, and therefore the electromagnetic

instruments of stealth aircraft. Ceramic is available in several grades and

therefore the application often determines the grade appropriate to be used.

Magnets like Rare Earth

Magnet is essential to be used in disk drive memories to supply needed

data storage. Without magnets, recording of music would be far more difficult.

Permanent magnets are essential to the production of green energy and lots of other

uses.