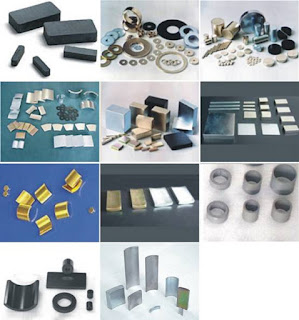

The term rare earth magnet is a generic name that is used to describe two types of magnetic material: samarium cobalt and neodymium iron boron. These two magnetic alloys utilize rare earth elements and Magnetic WeldingHolder as the magnetic constituents and the characteristics that these both material offers lend themselves to specific applications.

30 years ago in response to the rising cost of samarium cobalt, neodymium magnets were developed by General Motors and Sumitomo Specialty Metals. Neodymium iron boron has undergone numerous enhancements since its inception, and at present, this material is the most popular and widely used magnet alloy. It’s very much necessary to know that there are hundreds of patents covering the production of sintered neodymium iron boron magnets. At Dura, the neodymium iron boron supplied is licensed and compliant with all applicable patents.

Among all magnetic materials (including other rare earth), the highest available magnetic energy density with BHMax values ranging from 33 to 52 MGOe is offered by neodymium iron boron. When compared to other magnetic materials this physical property allows designers to use relatively small amounts of magnetic alloy.

However, the increased savings associated with neodymium and the smaller magnets might suggest you in selecting a high strength Rare Earth Magnet as the perfect choice among all applications but this is not always the case. Factors that cause premature failure and substandard performance are ignoring important characteristics such as operating temperature or the magnet’s ability to withstand corrosion. You will find the availability of alternative high-temperature grades of neodymium iron boron and various surface treatments when the rigors of the application demand it.

Apart from the fact that both are called rare earth magnets, there are few similarities between samarium cobalt and neodymium iron boron. With BHMax values ranging from 16 to 32 MGOe samarium cobalt offers the second-highest energy density, but SmCo magnets are also very brittle. Due to this physical characteristic, while integrating samarium cobalt magnets with a given application it is important that designers and engineers must take great care. Samarium cobalt because of its capacity to function at elevated temperatures up to 662°F sets itself apart from other magnet materials. For high strength/high-temperature applications samarium cobalt is often the rare earth magnet alloy of choice.

No comments:

Post a Comment