Welding is definitely not a simple work. You need to weld iron together, be on your feet on certain days, work it out, and that's what things like.

A

few different times you would require additional hands and work area for

comfort and to improve occupations, however they will not be accessible.

Nonetheless, very much like most things and occupations, welding has developed

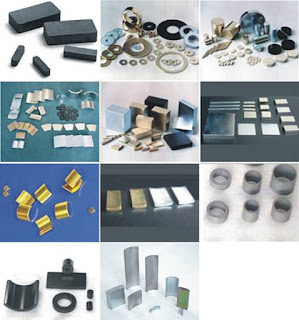

over the course of the years as well as instruments like Magnetic Welding Holder that are accessible for welding.

All

the more in this way, they are more secure and more proficient than utilizing

hands.

To

utilize them, you spread out the materials you need to weld together, then, at

that point, hold them with attractive braces at the two edges you need to weld,

and begin welding.

Support efficiency

Working

with attractive clips makes you work quicker than you would assuming you

utilized your hands. You don't need to stop at stretches to hold the metal set

up. With attractive cinches, they simply stay set up while you take care of

your responsibilities. You can wrap up rapidly with one and continue on to

another and finish things rapidly. They are way better compared to tighten

cinches.

Establishing

the base is more straightforward

Utilizing

attractive cinches to work with metals where just the bases are uncovered makes

the work more straightforward. Thus, you can utilize attractive clips to keep

the two bases intact and you'll get better and more productive welding results.

A superior use for

working with metal sheets

It's

smarter to utilize Magnetic Chuck

while welding sheets of metals. You don't have to do numerous apparatuses, and

you can undoubtedly weld them together. Additionally, it saves the expense of

employing or utilizing an additional hand to keep the metals intact.

Better for lines and

sporadic sheets

While

working with unpredictable pieces like lines that you can barely keep intact

set up with hands, you're in an ideal situation utilizing attractive cinches.

They will hold the sporadic pieces set up while you weld the spots you really

want to. The result will be smooth and amazing contrasted with utilizing your

hands.