As electromagnetic chucks can

provide variable holding power this is the reason which greatly improves their

ability to support a wide range of machining applications.

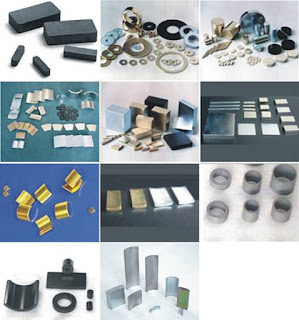

For holding Ferro-metallic work

pieces with a strong, uniform holding force magnetic chuck from Magnet

Manufacturer are designed. They constitute accurately centered

permanent magnetic face that works in conjunction with an operator actuated

permanent or electromagnet. To create a secure anchor for the work piece the

work piece closes the magnetic loop.

Shop Safety

Over permanent magnetic chucks the

variable holding power of electromagnetic chucks give it an advantage. But

their selection generally depends both on the machining application and shop

safety. Since, to operate Motor arc Magnets

need constant power but a power failure can introduce a worker safety concern.

While to address these concerns

uninterruptible power supplies, power conditioners and battery backup systems

can be integrated into the machining operations but on the design of a

particular machining application the ultimate decision relies.

Electromagnetic Chuck Operation

The constructions of

electromagnetic chucks are with electrical coils wound around a steel core

embedded in the chuck. A chuck controller from Magnet

Factory in China is used to generate a variable DC voltage in the

chuck's coils to energize the electromagnetic field. Electromagnetic field of

the coil causes particles within the Ferro-metallic work pieces to be aligned

in a common direction.

Between the work piece and the

chuck this alignment creates the electromagnetic holding force. As long as

voltage is applied the chuck's poles are magnetic. To vary the strength of the

magnetic field the operator can adjust the controller's DC voltage, which, in

turn, provides the variable holding force.

The Variable Holding Power Advantage

The chuck's ability is improved

by the variable holding power to support a wide range of machining applications

that include shaping, cutting, milling, EDM, high speed cutting operations and

thin work for grinding. For automation purposes electromagnetic chucks can

easily be interfaced with machine centers.